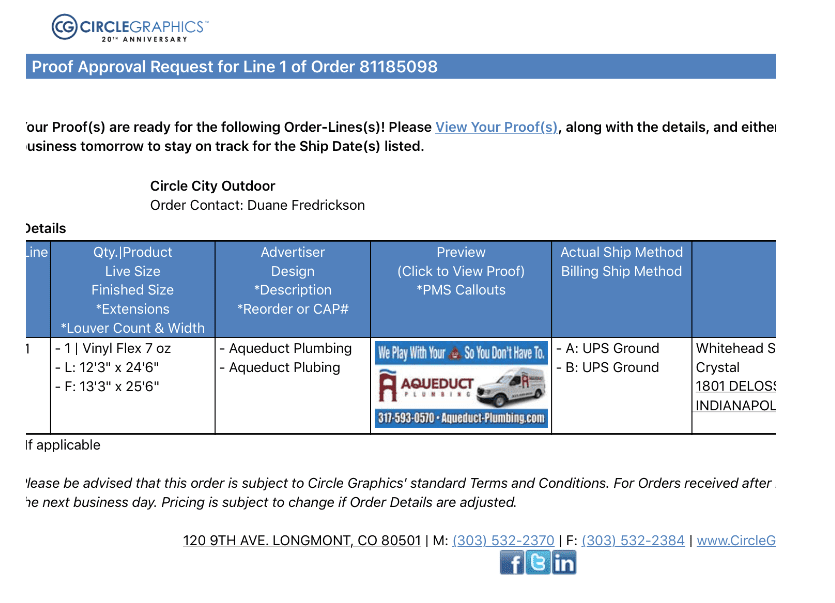

Curious how a vinyl billboard ad is produced. Circle Graphics Out of Home Division President Rod Rackley walks Billboard Insider through the steps in production. We used an actual Circle City Outdoor print job because Circle Graphics is the company’s printer.

The out of home company uploads the ad into the Circle Graphics system using our cloud based software. As the art file passed a quick inspection in prepress, we begin to build and add information to the file, including bleed, print registration marks, barcodes for production and shipping processes, and the ultimate print file.

Our automated DWF (digital workflow) system does many of these functions and even sends an automatic proof to a customer if the customer has requested that option.

The DWF works through a complex system of Hotfolders and Hotservers which perform specific tasks based on product type. Over a million lines of programming code coordinate the movement and analysis of files between Hotfolders and Hotservers.

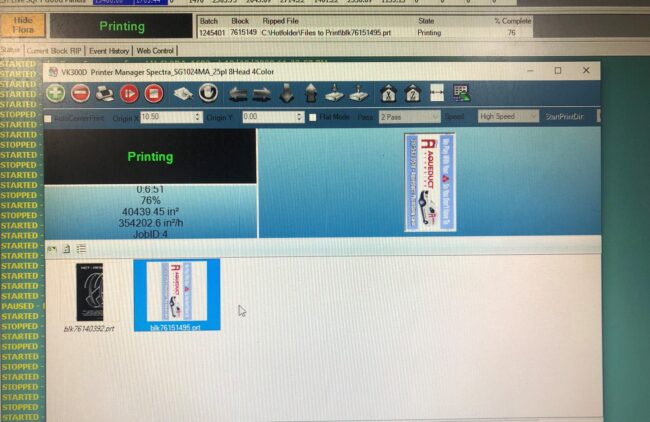

Once your file is ready to print, it is automatically scheduled via our Print Queue Manager (PQM) to a printer (see printer interface below).

Circle’s three OOH factories have enough print capacity for the entire OOH industry. Depicted here is our new Flora OOH platform which can print a 14×48 billboard in 15 minutes. These images depict what we call the take-up phase as the printed image comes off the press in a long, seamless roll.

A few freshly printed billboards on their way to postpress

In postpress, we cut the bulletin flex to size, fold and weld pockets, perform visual QC and measure each board, before folding and shipping the flex.

Boxed and ready to ship to the posting company!

And the completed and installed job.

[wpforms id=”9787″]

Paid Advertisement